PCB Assembly and Testing

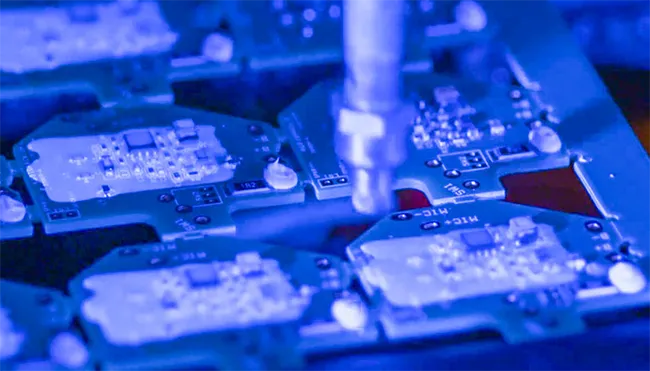

PCB Assembly

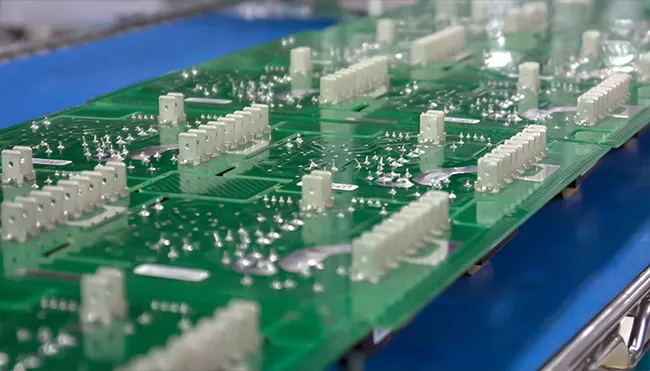

We have 30+ years of experience building high complexity SMT and PTH PCBA’s for customers in high-reliability market spaces.

- IPC/J-STD Class 2 and 3

- Rigid, Rigid-Flex, and Flex experience

- NPI support

- Higher mix, low to medium volume production support

- Sustaining/EOL product management

- Leaded and RoHS processes

- Water Soluble, RMA and No Clean Processes

- BGA and uBGA placement

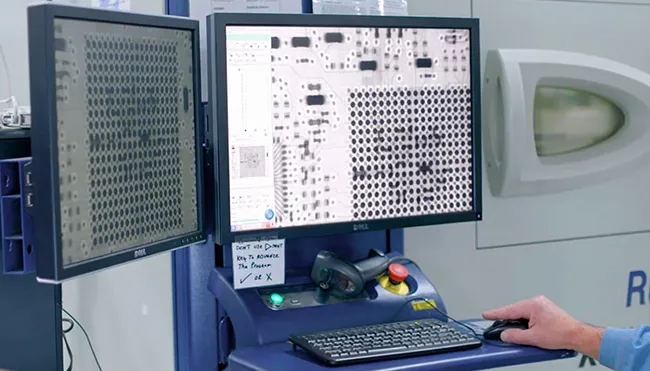

- 3D X-Ray of bottom terminated devices

- Passive components down to 0201 and 01005

- Secondary operations including Wave Solder, Selective Solder, and Conformal Coating/Staking/Potting

- Aqueous Wash and Cleanliness Verification

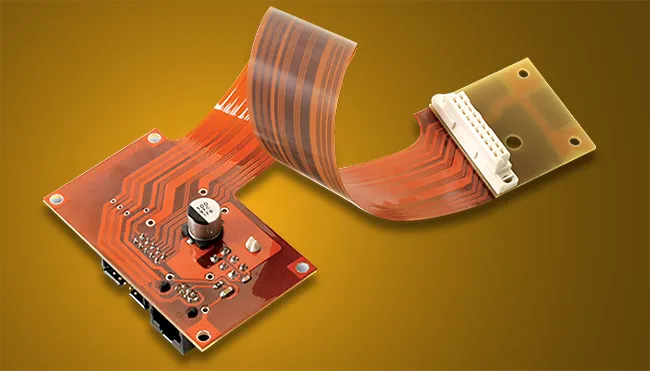

Flexible Circuit Assembly

Flexible circuit boards have grown in popularity to accommodate tight electronic packages and electrical connections where board thickness or flexibility is a factor. To meet this need, 4FRONT offers flexible circuit board assembly services. Our Design for Manufacturing (DFM) support capabilities combined with our state-of-the-art equipment enable us to assemble flexible circuit boards to meet all environmental and performance specifications.

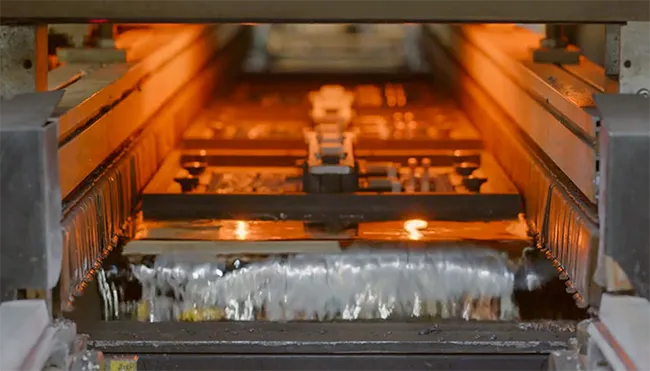

Through-Hole Technologies

Supporting legacy product is a core competency for 4FRONT. We have machine placement capabilities to support axial, radial, and dip packages. The idea is to auto-insert everything that we can, minimizing handling and building quality into the product that we supply. For those parts that do not lend themselves to automation, our experienced operators are J-STD-001 certified and trained on the latest soldering techniques.

- Axial, Radial, DIP Auto Insertion

- Mechanical Insertion Equipment

- Sequencing

- Side Lines

- Selective Wave, (RoHS and SnPB)

- Wave Solder (RoHS and SnPB)

- J-STD-001 Bench Soldering (Class II or III)

Conformal Coating and Potting Services

For customers whose products require a moisture barrier or stability for an envioroment that lends itself to shock and vibration, 4FRONT offers conformal coating and potting services. Our state-of-the-art automated conformal coating system is capable of applying Silicon and Acrylic layers down to one (1) mil thickness. The automation of our conformal coating process greatly reduces the manual taping and de-taping required for most coating applications -- improving quality while reducing cost. Additionally, we are fully capable of potting very small to large cavities with very high yield rates using single and two part potting materials.

- Acrylic, Silicon, Polyurethane

- Thickness is monitored using SPC controls and conveyorized black lighting for the inspection of coating coverage.

- Potting (1 and 2 part chemistries)

Testing Solutions

We believe that product test strategy begins at product conceptualization – long before a mature assembly is ever produced. We have a dedicated team to assist you with product test strategy, implementation, and qualification.

When ICT test fixtures may be cost and time prohibitive, we offer flying probe testing. We offer full functional testing using customer provided and/or in-house test fixtures. We have extensive experience in RF Testing and Tuning Systems. Our customers utilize our environmental test chambers and burn-in racks so they can validate and monitor product quality and reliability. Test data is scanned in by serial number and first pass yield is automatically calculated. Test data is easily reported through our automated quality management system.

- Flying Probe Test and Development

- In-Circuit Test and Development

- Functional Test and Development

- Environment Stress Screening Test and Development

- X-Ray Capabilities

- XRF for element and chemical analysis